I-SPCCipuleti lensimbi

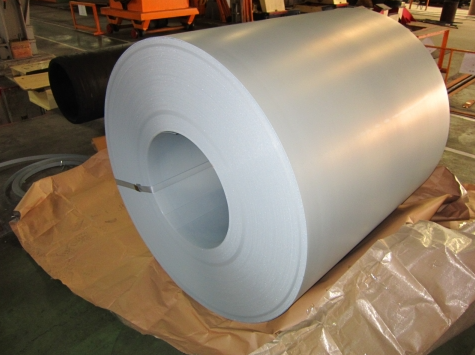

Ipuleti lensimbi le-SPCC liyi-aipuleti lensimbi eligoqiwe elibandayoecaciswe ku-Japanese Industrial Standard (jis g 3141).Igama layo eliphelele lithi "ikhwalithi yokuhweba egoqekile yensimbi ebandayo", lapho i-spcc imelela izici nokusetshenziswa kwaleli puleti lensimbi: s imele insimbi., p isho ipuleti eliyisicaba, u-c usho izinga lokuhweba, kanti u-c wokugcina usho ukugoqa okubandayo.Le nsimbi iyipuleti lensimbi elinekhabhoni ephansi evame ukusetshenziselwa ukwenza izingxenye zeziqandisi ezintsha, iziqandisi ezincishisiwe noma amabhande okuthutha izimoto ezizenzakalelayo.Leli cwecwe lensimbi linezakhiwo ezinhle kakhulu zokwakha nokugxiviza, futhi lingacutshungulwa ngokugxiviza okubandayo okujulile.Ngenxa yokuqukethwe kwayo kwekhabhoni ephansi, inezakhiwo ezingezinhle zemishini kodwa ineplastikhi enhle, okwenza kube lula futhi kube lula ukuyibumba ibe osayizi abahlukene.Yize ipuleti lensimbi le-spcc lingafaneleki kangako ezinhlelweni ezidinga amandla aphezulu, lisasetshenziswa kabanzi ezimbonini eziningi ezifana nemishini yasendlini nezimoto.Ngasikhathi sinye, le nto futhi inokumelana nokugqwala okuhle kakhulu futhi isetshenziswa kabanzi ezikhathini ezinezidingo eziphakeme kakhulu.

Ukwelashwa okungaphezulu kwepuleti yensimbi ye-spcc kungenziwa ngezindlela eziningi.Nazi ezinye izindlela ezijwayelekile:

Ukuhlanza ngomshini: Sebenzisa amathuluzi afana namabhulashi ocingo noma i-sandpaper ukuze upholishe futhi ugeze indawo engaphezulu ukuze ususe ukungcola okufana nokugqwala namafutha.

Ukwelashwa ngamakhemikhali: ukusebenzisa i-asidi, i-alkali noma amanye ama-reagents amakhemikhali ukuncibilikisa noma ukuguqula ama-oxide angaphezulu noma okunye ukungcola kube izinto ezihlanzekayo ukuze kufezwe inhloso yokuhlanza indawo engaphezulu.

Ukwelashwa kwe-Electroplating: Ukufakwa kwensimbi kwenziwa phezu kwepuleti lensimbi ngokusebenzisa i-electrolysis ukuze kukhiqizwe ungqimba lwensimbi evikelayo ukuze kuthuthukiswe ukumelana nokugqwala nokubukeka kwayo.

Ukwelashwa kokumboza: Fafaza ngemibala ehlukahlukene kapende ebusweni bepuleti lensimbi le-spcc ukuze udlale imisebenzi yokulwa nokugqwala kanye nokwenza ibe muhle.

Izindlela ezihlukene zokwelashwa kwendawo zifanele izidingo ezihlukene zezimboni.Ukukhetha indlela efanelekile yokwelapha ingaphezulu lepuleti lensimbi le-spcc ngokwesimo sangempela kunganweba impilo yayo yesevisi futhi kulondoloze izakhiwo ezinhle kakhulu zokusebenza.

Ipuleti yensimbi ye-SECC

Igama eliphelele le-SECC yinsimbi, i-Electrolytic Zinc-coated, Cold Rolled Steel Coil, okuyipuleti lensimbi elivuthwa ngogesi ngemva kokugoqeka okubandayo.Indawo engaphezulu ifakwe i-electrolytically galvanized ukuze ibe nokusebenza okungcono kokunqanda ukugqwala kanye nobuhle.Ivamise ukusetshenziselwa ukukhiqiza imikhiqizo enokusebenza okuphansi kwe-anti-corrosion kanye nezidingo zokuhlobisa, njengama-casings ezinto zikagesi zasendlini, ama-instrument casings, njll.

Indlela ye-SECC yokuqinisa:

Ikhoyili Efakwe Ngamanzi Eshisayo: I-Hot-dip galvanizing iwukwelapha okunqanda ukugqwala okwakha ungqimba lwezinki ebusweni bensimbi.Iwukucwilisa amapuleti ensimbi noma izingxenye zensimbi oketshezini lwezinki oluncibilikisiwe olushiswe kusengaphambili kuzinga lokushisa elifanele (imvamisa engu-450-480 degrees Celsius), bese kwakheka ugqinsi oluminyene lwengxube yensimbi ye-zinc-iron ebusweni bezingxenye zensimbi ngokusabela.Vikela izingxenye zensimbi ekugqwaleni.Uma kuqhathaniswa ne-electrolytic galvanizing, i-hot-dip galvanizing inokumelana nokugqwala okuphezulu nempilo yesevisi ende, futhi imvamisa isetshenziselwa ukukhiqiza imikhiqizo ebalulekile efana nezingxenye ezinkulu zesakhiwo, imikhumbi, amabhuloho, kanye nemishini yokuphehla ugesi.

Indlela eqhubekayo yokufaka uthayela: Amashidi ensimbi agoqiwe acwiliswa ngokuqhubekayo kubhavu lokucwenga eliqukethe i-zinc encibilikile.

Indlela yokufaka ucwecwe: Ipuleti lensimbi elisikiwe licwiliswa kubhavu wokucwenga, futhi kuzoba khona isiphalazi se-zinc ngemva kokucwetshwa.

Indlela ye-Electroplating: i-electrochemical plating.Kunesixazululo se-zinc sulfate ethangini lokucwenga, elinezinc njenge-anode kanye nepuleti lensimbi lokuqala njenge-cathode.

I-SPCC vs SECC

I-SECC galvanized steel sheet kanye neshidi lensimbi elibandayo le-SPCC yizinto ezimbili ezihlukene.Phakathi kwazo, i-SECC isho amashidi ensimbi agingqiwe abandayo afakwe ugesi, kuyilapho i-SPCC iyindinganiso yeshidi lensimbi egoqelwe yonke indawo.

Umehluko wabo omkhulu yilezi:

Izakhiwo ezibonakalayo: I-SECC ine-zinc enamathela futhi inokumelana nokugqwala okungcono;I-SPCC ayinaso isendlalelo esilwa nokugqwala.Ngakho-ke, i-SECC iqinile kune-SPCC futhi ivimbela ukugqwala nokugqwala.

Ukwelashwa okungaphezulu: I-SECC ithole i-electrolytic galvanizing nezinye izinqubo zokwelashwa, futhi inezinga elithile lokuhlobisa kanye nobuhle;kuyilapho i-SPCC isebenzisa inqubo yokugoqa ebandayo ngaphandle kokwelashwa okungaphezulu.

Ukusetshenziswa okuhlukile: I-SECC ivame ukusetshenziselwa ukwenza izingxenye noma ama-casings emkhakheni wezinto zikagesi, izimoto, nezinto zikagesi zasendlini, kuyilapho i-SPCC isetshenziswa kabanzi ezimbonini ezifana nezokwakha, ezokukhiqiza, nokupakisha.

Ngamafuphi, nakuba zombili izingcwecwe zensimbi ezigoqeke ngokubanda ngokwezingxenye zenqubo, kunomehluko ophawulekayo ezicini zabo zokulwa nokugqwala, ukwelashwa kwendawo kanye nokusetshenziswa.Ukukhethwa kwe-SECC noma ipuleti lensimbi ye-SPCC kufanele kunqunywe ngokusekelwe esimweni esithile, kucatshangelwa izici ezihlukahlukene ezifana nokusetshenziswa komkhiqizo okhiqizwayo, imvelo kanye nezidingo zangempela, nokukhetha impahla efanele kakhulu.

Isikhathi sokuthumela: Nov-06-2023